Why Does a Compressed Air Dryer Need a Water Separator?

Posted on July 29th, 2021

If your system already has a compressed air dryer installed, you might be asking why you also need a water separator. It may seem redundant to install an additional product that’s purpose is also to keep the air dry. However, without pairing the two together, your system may experience costly issues.

The Basics of Moisture in a Compressed Air System

Atmospheric air contains water vapor. Accordingly, your compressor brings water vapor straight into the airflow. Air is compressible, but water is not. Meaning, as the air volume starts to become smaller during the compression process, there is progressively less room for water vapor. As the vapor’s space shrinks, the vapor condenses into aerosols, and then eventually into a liquid form. Additionally, the air can hold a given amount of moisture in vapor form at any given temperature.

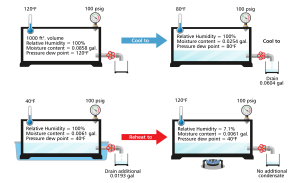

The air temperature drops as it moves downstream of the compressor, allowing more water vapor to condense into aerosols and then liquid. As a rule of thumb, for every 20°F (-6.7°C) drop in temperature, the air’s capacity to hold water vapor is cut in half. When the air passes through a system, there are more opportunities for the remaining water vapor to turn into a liquid as the temperature decreases. If the liquid water is not caught and removed, it will continue through the system, potentially causing a wide range of problems.

The figure below, provided by CAGI, demonstrates the compressed air’s capacity to hold water vapor at different temperatures.

Risks of Aerosols & Liquid Water in an Air System

The liquid that is allowed to pass downstream in a compressed air system can cause a wide range of problems. The most common being:

- End-product spoilage

- Rusting components

- Harmful breathing air

- System downtime

- Wet pneumatic control valves

Furthermore, suppose the temperature continues to decrease below freezing, and the water vapor has not been removed. In this case, pneumatic control valves could freeze, and blockages could occur inside the pipework.

The Difference Between Dryers and Water Separators

Although dryers and water separators both work to remove moisture from compressed air, their functions are very different. A water separator efficiently removes aerosols and liquid water from an air stream, while a compressed air dryer works to remove the water vapor.

It is essential to remove both liquid water and water vapor if you want to eliminate condensation in the rest of the compressed air system. By removing water vapor, a dryer can reduce the dew point to well below the system’s lowest possible air temperature.

Protect Your Dryer

The high efficiency coalescing filters that are typically located at the dryer’s inlet are not designed to remove large amounts of liquid. If there is a high amount of fluid, there could be damage done to the prefilter and cause the liquid to reappear back into the airflow.

The ability of a regenerative dryer to remove water vapor can be negatively impacted by the presence of aerosols and liquid water in its inlet. Liquid water can damage the desiccants used in regenerative dryers if allowed to enter the dryer over an extended period. If there is a heavy demand for the dryer, the chances of damage increases. Therefore, it is vital to ensure that all aerosols and liquid water are removed before entering the dryer.

Aerosols and liquid water can reduce efficiency in other types of dryers as well. For example, bulk water can reduce refrigerated dryers’ heat transfer efficiency, potentially overwhelming the internal water separator, resulting in higher outlet dew points.

Water Separators: Low-Cost, High-Value Solution

In most systems, the water separator removes the majority of water from the airflow by eliminating aerosols and liquids. Water separators employ mechanical centrifugal spinners that do not require replacement. They also can help keep operating costs low because they offer very little resistance to the airflow.

Water separators are much less expensive than dryers. Additionally, they do not require regular service, making it one of the most affordable products in a system. For its cost, a suitable water separator provides a very high value.

Protect Your System

Including both dryers and water separators in your system will save you money by eliminating the many costly issues.

Walker Filtration’s regenerative compressed air dryers are highly efficient, providing reliable performance in a wide range of applications. Additionally, our water separators remove up to 99% of the liquid water from compressed air, making them an economical and efficient solution. We are so confident in our water separators that we insist on their placement in front of their dryers as a warranty condition.

Learn more about our water separators HERE. Please contact our sales team with any questions at USA@walkerfiltration.com.